Representatives of VSee customer Saudi Aramco and its solution partner Perfomix presented a paper today at the Society of Petroleum Engineers 2009 Digital Energy Conference. Entitled Operational Innovation with Real-Time Collaboration and Exception Management in Exploration & Production Industry, the paper described how Saudi Aramco used VSee over a satellite link in oil exploration to connect its Geosteering Operations Center (GOC) to remote drilling rigs and to geoscientists/engineers in their offices or even at home. The system is called the GOC Gateway and is described as follows:

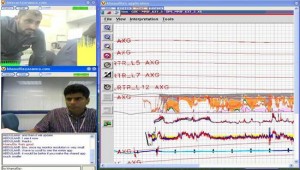

Using the Gateway, operation geologists can conduct a video conference with the rig Forman and share their geological cross sections and maps, and any of them could take control of the shared application, zoom in, zoom out and make notes, which makes it just like they are meeting in the same room [figure at right].

GOC Gateway bridges the distance between GOC and remote drilling rigs which is in range of a few hundred km, various RTOCs and geoscientist’s/engineer’s offices. This type of remote collaboration has provided better and faster decision making process since GOC could consult very quickly with rigs, field characterization geologists, drilling engineers and management, very efficiently using this technology. Also, the tool reduces the need for senior geologists and engineers to visit the center when they are needed, especially after hours, which will avoid the risk of accidents and increase employee’s safety.

The paper goes on to describe the benefits:

The solution example discussed above, has dramatically improved team collaboration and bridged the distance between real-time operation centers and remote sites. This has resulted in a faster and better decision making process. Also, it reduced the rig downtime and optimized the entire drilling operations which are very costly. Furthermore, it optimized manpower required to operate real-time centers and increased safety, since it reduced transportation and commuting to the center when some special skills or expertise are required during nonworking hours.